Intelligent monitoring management. Better sleep.

Monitor and analyze alarms and bypass for a healthier, safer, and more productive plant.

Solution

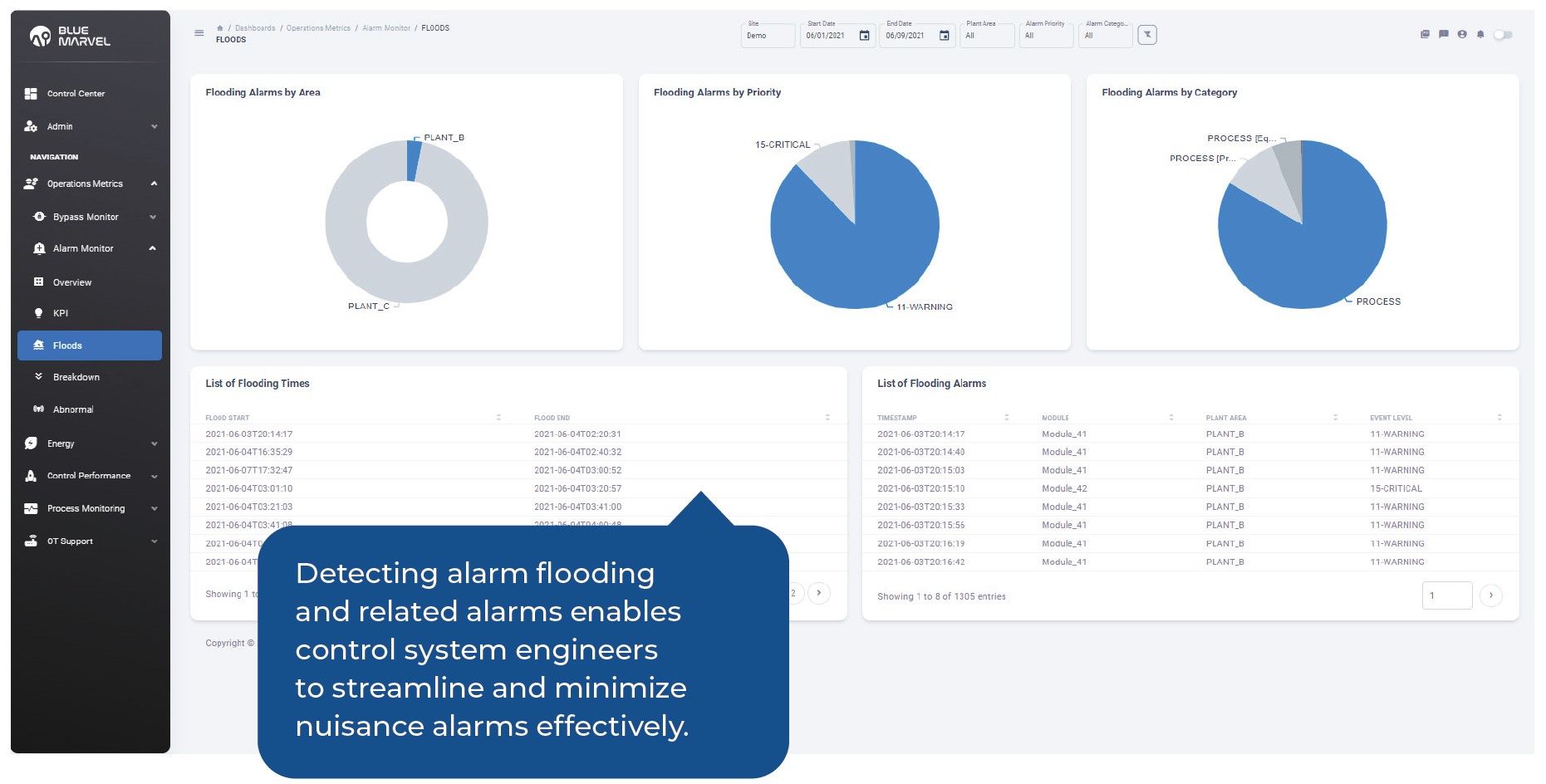

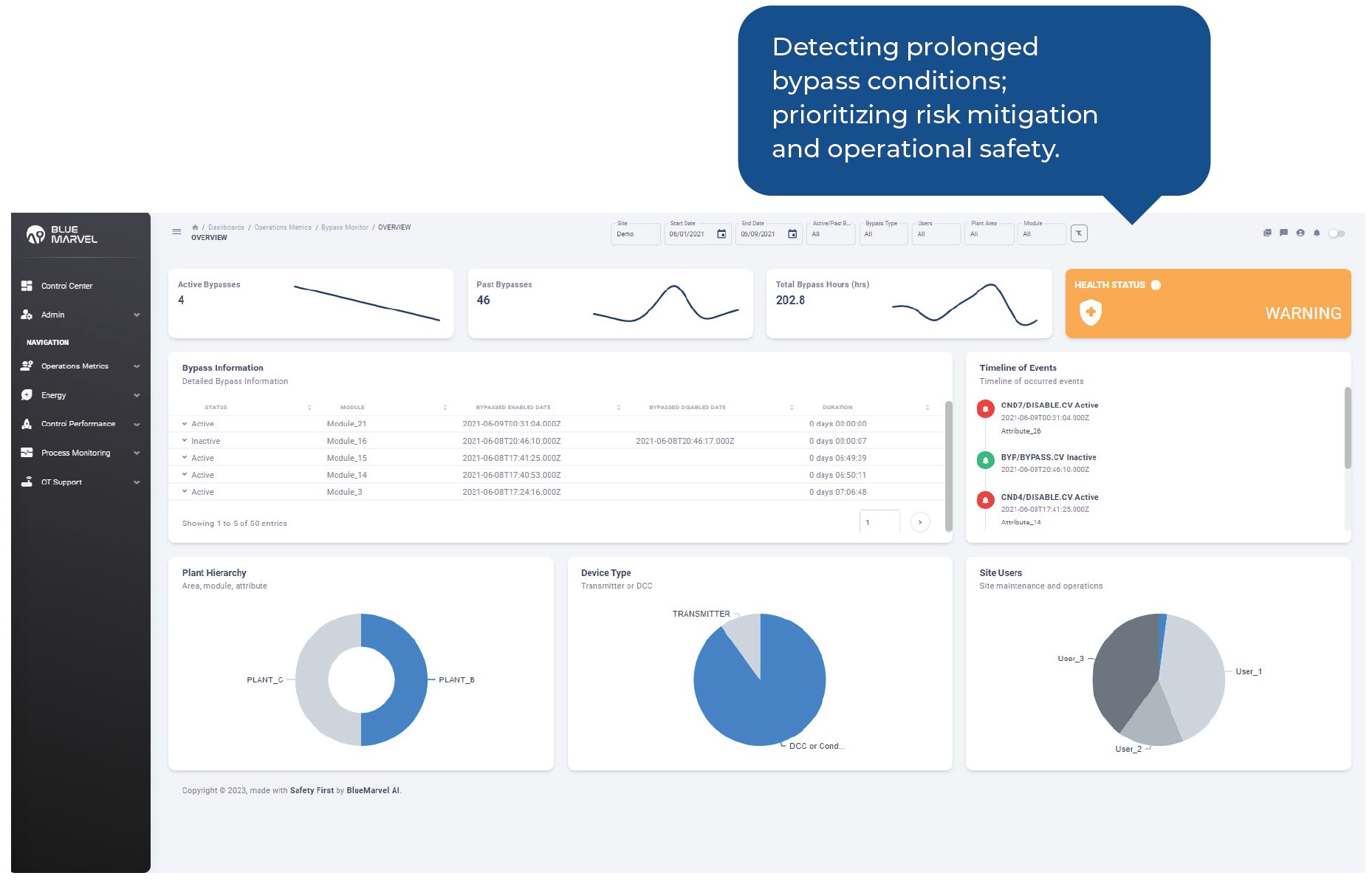

A cloud-native application that liberates and consolidates operating alarm & event data from industrial sites and provides visibility to important KPIs that reflect the operating team workload and activities within the plant. It has been developed to help improve operating performance and eliminate risk and safety incidents related to operator overload and error.

Our application enables local and corporate operating, engineering, safety, risk, and training teams to conduct audits and benchmarking studies to generate insights to improve process safety, mitigate industrial risk, enhance operator training, and increase operational efficiency.

Addressing these needs will ultimately result in a more efficient and positive work environment for the operations team, enhancing safety, reliability, and profitability.