The use of hydrogen in natural gas networks can help reduce carbon emissions and improve the overall efficiency of the natural gas system. The blending of hydrogen with natural gas also enables the use of existing natural gas infrastructure, reducing the need for costly upgrades or new infrastructure. By implementing hydrogen blending, operators can reduce greenhouse gas emissions and take a step towards a more sustainable energy future.

Hydrogen Blending & Injection in Natural Gas

Hydrogen (H2) is most commonly blended with natural gas. The amount of H2 in the blended gas depends on the application and the properties of the existing gas infrastructure.

Hydrogen produced from renewable energy sources can be injected into natural gas pipelines or onsite at industrial facilities. The resulting blends can be used to generate heat and power with lower emissions than using natural gas alone due to hydrogen's greater combustion efficiency.

Benefits of Blending

The use of hydrogen in natural gas networks can help reduce carbon emissions and improve the overall efficiency of the natural gas system. The blending of hydrogen with natural gas also enables the use of existing natural gas infrastructure, reducing the need for costly upgrades or new infrastructure. By implementing hydrogen blending, operators can reduce greenhouse gas emissions and take a step towards a more sustainable energy future.

Lakeside's Blending Solutions

Lakeside is at the forefront of developing and implementing cutting-edge hydrogen blending systems with natural gas. We offer a wide range of services including designing, fabricating, installing, and commissioning hydrogen blending systems tailored to meet the unique requirements of our clients.

We utilize state-of-the-art technology and advanced engineering techniques to deliver top-quality hydrogen blending systems that are reliable and environmentally sustainable.

We recognize the importance of staying ahead of the curve in terms of innovation and development. As such, we continually strive to improve our technology and processes to remain at the forefront of the hydrogen blending systems industry. We take pride in providing our clients with solutions that are safe, efficient, and cost-effective, while also promoting a sustainable future.

Blending Technology

The successful implementation of hydrogen blending in natural gas utilities requires a comprehensive solution that addresses both accurate injection & blending of hydrogen and prevention of leakages and/or permeation.

Accurate Injection and Blending of Hydrogen

Accurate injection and blending of hydrogen are essential to ensure that the blended gas meets the desired specifications and is safe to use. This requires precise control over the flow rate and composition of both natural gas and hydrogen, as well as careful monitoring of the blending process to ensure that the two gases are thoroughly mixed.

Accurate gas concentration and heating values are crucial in hydrogen blending applications to ensure optimal fuel performance, efficiency, and compliance with gas quality standards/contractual agreements. When hydrogen is added to natural gas, it can impact the quality of the gas and its combustion characteristics. This can lead to changes in the Wobbe Index, which is a measure of the heating value of the gas. To ensure that the blended gas maintains the desired heating value with appropriate combustion characteristics, it is important to monitor the blending process.

The Rosemount 770XA Gas Chromatograph is a metrology-approved analyzer that provides highly accurate measurement of the energy content of blended gas. This advanced analyzer uses gas chromatography to separate the individual components of the gas blend, providing a precise measurement of the concentration and energy content of each component. This information can be used to calculate the Wobbe Index and ensure that the blended gas maintains the desired heating value. By utilizing the Rosemount 770XA Gas Chromatograph in hydrogen blending applications, operators can ensure accurate and reliable measurement of the energy content of the gas blend, improving overall system efficiency and reducing the risk of equipment damage or failure.

It is important to ensure accurate injection of hydrogen as each natural gas network is designed for a specific blend, and this blend percentage must not be exceeded.

Accurate and reliable flow measurement is critical to ensure optimal performance and safety. Micro Motion ELITE Coriolis flow meters are designed to deliver high metering accuracy across a wide range of varying flow rates, making them an ideal choice for hydrogen and natural gas applications. These meters offer a high turndown ratio, which means that they can accurately measure flow rates ranging from low to high, without the need for recalibration or additional equipment.

Micro Motion ELITE Coriolis flow meters do not have any internal moving parts, which significantly reduces maintenance requirements and eliminates the need for periodic recalibration. Furthermore, the meters come equipped with advanced onboard diagnostics that provide real-time feedback on meter performance, ensuring that operators have confidence in the accuracy of the measurements. This feature also enables remote troubleshooting, allowing for quick and efficient resolution of any issues that may arise. By utilizing the Micro Motion ELITE Coriolis flow meters in hydrogen blending applications, operators can ensure reliable, accurate, and low-maintenance flow measurement, improving overall system efficiency and safety.

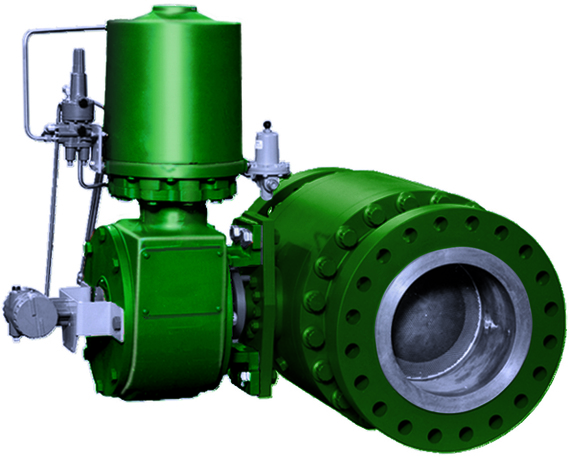

Control valves play a critical role in maintaining optimal pressure and flow rates of gases. However, high gas flow rates can create vibrations and excessive process noise, which can adversely impact the performance of control valves. Through proper control valve sizing and selection, users can achieve efficient and reliable performance, even at high gas flow rates.

Depending on process parameters, an appropriate Fisher Control Valve can leverage various features to overcome these challenges. For example, the Fisher V260 control valve utilizes a full-bore design, which ensures minimal pressure drop and increased flow capacity, resulting in efficient and reliable performance.

The Fisher V260 control valve is equipped with an integral drilled single or double stage attenuator that effectively controls noise and vibration caused by high pressure drop gases. This not only reduces the risk of valve damage and failure but also ensures a quieter and more stable operation. Through utilizing the appropriate Fisher control valve, users can achieve stable and precise gas control with reduced maintenance intervals, ensuring efficient and reliable gas flow management.

Prevention of Leakage and/or Permeation

Preventing leakage and/or permeation of hydrogen is crucial to ensure the safety of the distribution network and the surrounding environment. To prevent leakage, the distribution system must be designed with appropriate materials and components, including seals and valves that can withstand the corrosive properties of hydrogen. Regular maintenance and monitoring of the distribution system are also necessary to detect any leaks or potential safety hazards.

Hydrogen Embrittlement (HE) is the reduction in a material's ductility due to the absorbed hydrogen atoms, which can lead to failure of the material. Hydrogen atoms are small and can permeate into the piping material and lower the stress required for cracks to form. Prevention of HE is critical to ensure the safety and reliability of the hydrogen blending solution.

Pressure regulation is a critical aspect of hydrogen blending applications. Maintaining proper pressure levels in the blended hydrogen and natural gas network is crucial to prevent over-pressurization, which can lead to safety risks such as hydrogen embrittlement. To ensure safety and optimal system performance, it is important to use appropriate pressure regulators in the hydrogen blending process.

Fisher pressure regulators are highly accurate, stable, and reliable, offering precise pressure control, minimizing the need for onsite manual maintenance and reducing the risk of leaks. These regulators are designed to operate under the specific conditions required for hydrogen blending applications with a configuration that is specially designed to mitigate the risk of hydrogen embrittlement and leaks. By utilizing Fisher Pressure Regulators in hydrogen blending applications, operators can ensure optimal pressure regulation, minimize safety risks, and maintain the integrity of the blended gas network. Additionally, using the appropriate pressure regulators can help to ensure that the blended gas is delivered reliably and efficiently to end-users, contributing to overall system performance and efficiency.

It is critical to monitor for corrosion and erosion in gas pipelines to maintain the integrity and safety of the system. Hydrogen embrittlement can result in reduced ductile strength and ultimately lead to corrosion and pipe failure. To ensure reliable and safe operation, it is important to monitor pipe erosion on a regular basis.

The Rosemount Wireless Permasense Corrosion and Erosion Monitoring System provides a non-invasive solution for real-time monitoring of pipe thickness. This system uses ultrasonic measurements to provide accurate and reliable wall thickness data that is transmitted via a WirelessHART network to accompanying software. The software can then be used to make informed decisions about pipe maintenance and replacement, allowing operators to take proactive steps to prevent pipe failure and ensure system reliability. With the Rosemount Wireless Permasense Corrosion and Erosion Monitoring System, operators can detect and address issues with pipe erosion before they become a safety hazard or result in unplanned downtime. By proactively monitoring pipe erosion, operators can extend the life of their pipelines and ensure that the blended gas is delivered reliably and safely to end-users

Ensuring safety is of paramount importance in hydrogen blending applications due to the highly flammable nature of hydrogen. Even small leaks or equipment malfunctions can pose a significant risk to people and equipment. To prevent such incidents, it is crucial to have a robust safety system in place that includes leak detection, gas detection, and flame detection.

One solution for leak detection is the Emerson Incus Ultrasonic Gas Leak Detector, which uses ultra-sensitive acoustic sensors to continuously monitor for ultrasound signals generated from the release of pressurized gas. This technology is well-suited for outdoor environments and can withstand extreme weather conditions.

The Rosemount SC310 Catalytic Bead Combustible Gas Sensor is another reliable solution for gas detection, with fast and accurate detection of all flammable gas types and is designed for field serviceability. The sensor's robust construction also ensures it can withstand harsh environmental conditions, making it suitable for a wide range of applications.

Hydrogen fires are especially hazardous since they are invisible to the naked eye, making the Rosemount 975MR Multi-Spectrum Infrared Flame Detector a valuable tool for flame detection. This detector can accurately detect fuel and gas fires from long distances, providing early warning to avoid potential hazards. With a comprehensive safety system that includes leak detection, gas detection, and flame detection, you can mitigate the risks associated with hydrogen blending and ensure a safe environment for everyone involved.

Vanessa Triple Offset Valves (TOV) play a crucial role in hydrogen blending applications due to their exceptional performance in providing positive isolation and their zero leakage capabilities. In industries where safety is of utmost importance, these valves have become indispensable.

In hydrogen blending applications where hydrogen gas is highly flammable and poses a significant safety risk if not handled properly, the TOV is specifically designed to provide end-users with reliable, repeatable bubble tight shut-off. The TOV's metal-to-metal torque-seated design and triple offset geometry ensure that there is no room for leakage even in high-pressure and high-temperature applications. This design eliminates the need for gaskets and reduces wear and tear resulting in longer valve life and reduced maintenance costs. By using TOVs, end-users can rest assured that there are no leaks or unintended releases of gases through the valve, keeping personnel, equipment, and the environment safe.

Proven Results

Enbridge Hydrogen Blending Solution

Lakeside designed, built, and implemented the first hydrogen blending skid and analytics building in North America to blend hydrogen directly into a natural gas pipeline feeding homes in Markham, Ontario.